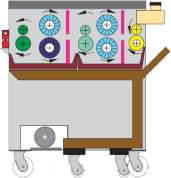

KD-Tray-Cleaner TUBUR 600 | 800 | 1000

KD tray cleaners for cleaning 2-edged baking trays and perforated plates Capacity: up to 1400 baking trays simul taneously cleaned and oiled per hour

Equipment

- Housing completely in stainless steel

- Fold-up cover with grip in stainless steel

- Ergonomic input-height of 850 mm

- Effective pre-scraper

- Pull-in rollers made of full material

- Four brushes with quick-fit couplings

- Discharching-rollers made of full material

- Dust-free oiling system

- One dirt drawer in stainless steel

- Built-in hole cleaning brushes for perforated trays as a second cleaning facility

- Housing completely in stainless steel

- Fold-up cover with grip in stainless steel

- Ergonomic input-height of 850 mm

- Effective pre-scraper

- Pull-in rollers made of full material

- Four brushes with quick-fit couplings

- Discharching-rollers made of full material

- Dust-free oiling system

- One dirt drawer in stainless steel

- Second cleaning station with our new development for improved hole cleaning

- One tray-trolley in stainless steel

- Oiltank with automatic level-control

- Hydro-package for improved wet-cleaning of the machine:

The HYDRO – PACKAGE for the KD-Tray-cleaning TUBUR -type machine optimizes the wetcleaning of the machine’s interior. It contains e.g.:- Two brushes in 1.4310 stainless steel

- Pre-scraper in 1.4310 stainless steel

- Motor IP 66

- All bearings and pressure-springs in 1.4301/1.4310 stainless steel

- Four caster wheels with housing in stainless steel, each for up to 700 kg weight

- Housing completely in stainless steel

- Fold-up cover with grip in stainless steel

- Ergonomic input-height of 850 mm

- Effective pre-scraper

- Pull-in rollers made of full material

- Four brushes with quick-fit couplings

- Discharching-rollers made of full material

- Dust-free oiling system

- Second cleaning station with our new development for improved hole cleaning

- One tray-trolley in stainless steel

- Oiltank with automatic level-control

- Hydro-package for improved wet-cleaning of the machine:

The HYDRO – PACKAGE for the KD-Tray-cleaning TUBUR -type machine optimizes the wetcleaning of the machine’s interior. It contains e.g.:- Brush in 1.4310 stainless steel

- Pre-scraper in 1.4310 stainless steel

- Motor IP 66

- All bearings and pressure-springs in 1.4301/1.4310 stainless steel

- Four caster wheels with housing in stainless steel, each for up to 700 kg weight

- Two-Tray-Stop (TTS) TTS prevents two trays being drawn into the machine simultaneously

- Mobile dirt drawer on wheels

- Dirt-barrier made of stainless steel with comb-brushes

Working Principle

You insert the baking ray – dirty side down – into the entry opening above the pre-scaper. It is then drawn into the machine by the feeding rolls and transported between the two fast revolving brushes which clean both sides of the tray dry. The discharching rolls extract the tray out of the brushes and pass it into the next cleaning station and through the greasing system.There the tray is greased dust free and then transported onto the tray trolley. The dirt is fallen into the large mobile dirt drawer accessible from the back of the machine. The loading height of 850mm (33.5″) is strandard at this model. Up to 100 baking trays are cleaned and greased simultaneously in 5 minutes.

Technical Data Basic / Comfort / Premium

| TUBUR 600 | TUBUR 800 | TUBUR 1000 | |

| Backing tray width | 250 mm – 600 mm | 601 mm – 800 mm | 801 mm – 1000 mm |

| Machine width | 920 mm | 1120 mm | 1320 mm |

| Machine depth without / with oil tank |

1050 /1100 mm | 1050 /1100 mm | 1050 /1100 mm |

| Machine height | 1050 mm | 1050 mm | 1050 mm |

| Weight approx. | 405 kg | 445 kg | 485 kg |

| Motor power 400V (3 PH+O+E) |

1,1 kW | 1,1 kW | 1,1 kW |